Weighing & Sampling Isolator

The buffer chamber and continuous bag system are used to achieve the airtight transfer of materials,

which can avoid the API exposure to the environment and injury to personnel.

Weighing and sampling operations are done in the isolator through gloves.

Feeding / Mixing Isolator

APIs with complete packages are passed into the dissolution isolator, where the unpacking, weighing, and dissolution operations are performed.

Electronic weighing device is used during the operation.

Vacuum Drying Isolator

The isolator is connected to the vacuum dryer. After the APIs is dried, the door of the vacuum dryer is opened in the isolator,

and the dried APIs is weighed and sub-packed in the isolator. The packaged APIs is passed out through the continuous bagging system.

After the isolator is inactivated and cleaned, the hatch is opened and all apparatus is taken out.

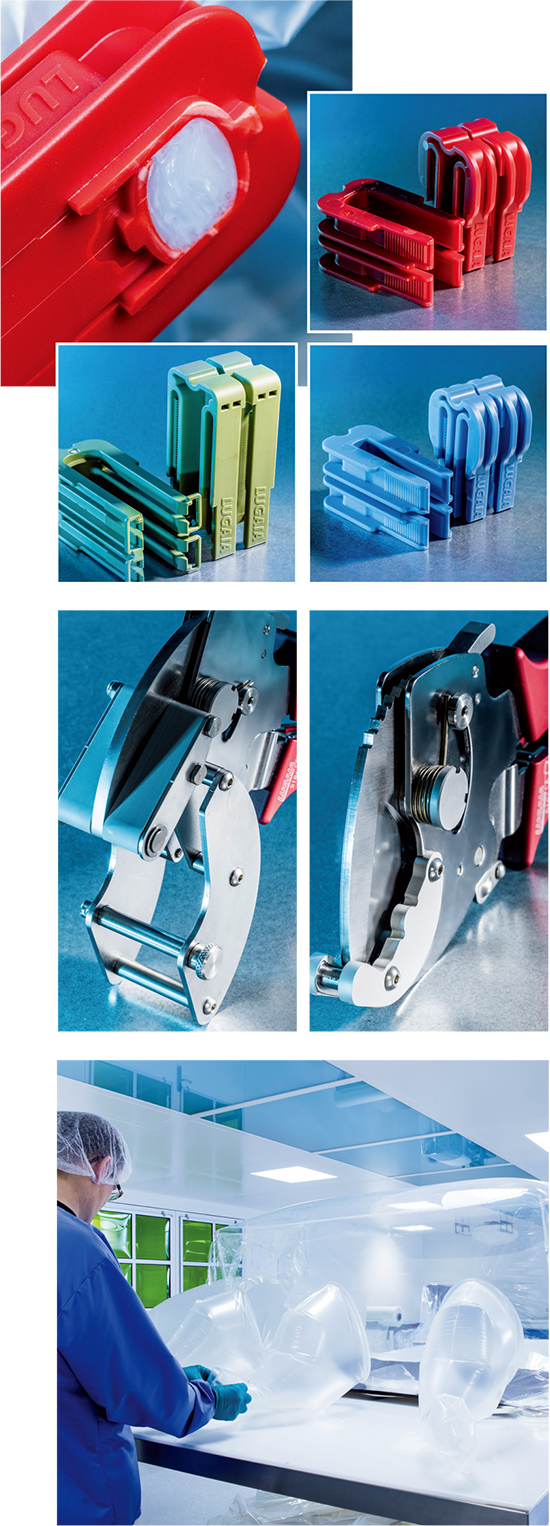

BIBO toolset and Bag Clips

CN

CN